Case Studies

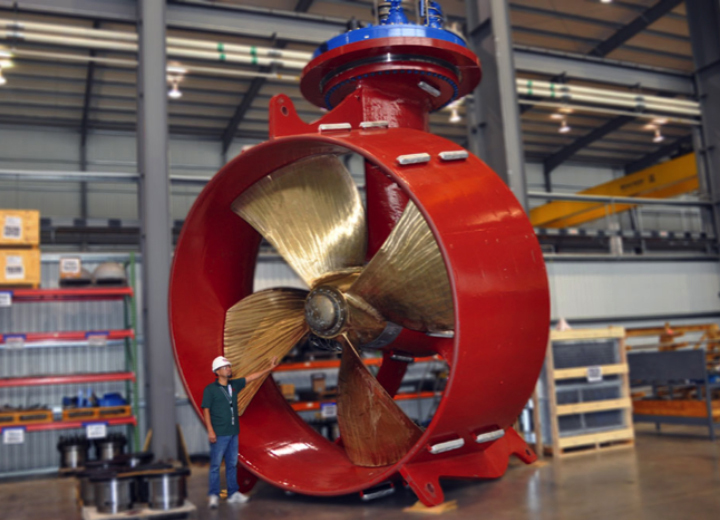

Dave’s leadership and experience were pivotal parts of Thrustmaster’s successful transformation. He provided us with a powerful blend of theory and practical learning uniquely tailored to fit our organization’s needs. He didn’t just tell us what to do, but instead helped us determine the right questions to ask and provided us with the right tools to find answers and implement solutions. This approach taught us how to adapt the Lean concepts and tools to the challenges of our high mix / low volume heavy manufacturing environment, and prepared us to be a self-sustainable lean company. Dave’s breadth of experience from Tool and Die Maker to Manufacturing Executive allowed him to quickly build rapport with members of our team from all levels and disciplines, both in the plant and in the office. Within 18 months of working with Dave, Thrustmaster achieved significant improvements in first time quality, on time delivery, and overall costs. More importantly, we achieved a sustaining culture of success through problem solving and continuous improvement.

Jason Small

General Manager | Thrustmaster of Texas

Thrustmaster.net

“I was very fortunate to have Ron Taylor as my improvement coach during my tenure as COO. I particularly appreciated the focus on improving the capability of our team and his commitment to ensuring we maintained ownership of our journey. As a result we met or exceeded targets in quality, cost, LOS, patient satisfaction and employee engagement.

Lisa Strom

former Hospital COO

“Dave is forward thinking with a focus on process development and lean optimization.”

Mr. Bill Michel

Vice President

Uflex North America